Cape

Cape Timber Frame Design

Designed by: Timberworks Design

Style: Barn,Cape

Nominal Size: 24' x 24'

Square Footage: 1008 sf

Bedrooms: 0

Bathrooms: 0

Projects

Projects based on or similar to this design.

If nothing shows here it simply means we don't have pictures of the projects based on this design.

As with most of the timber frame designs on this site (Bite the Frost Designs are the exception), this is a stock design for you to start with. Use the Request an Estimate form to get started with this design.

What we provide:

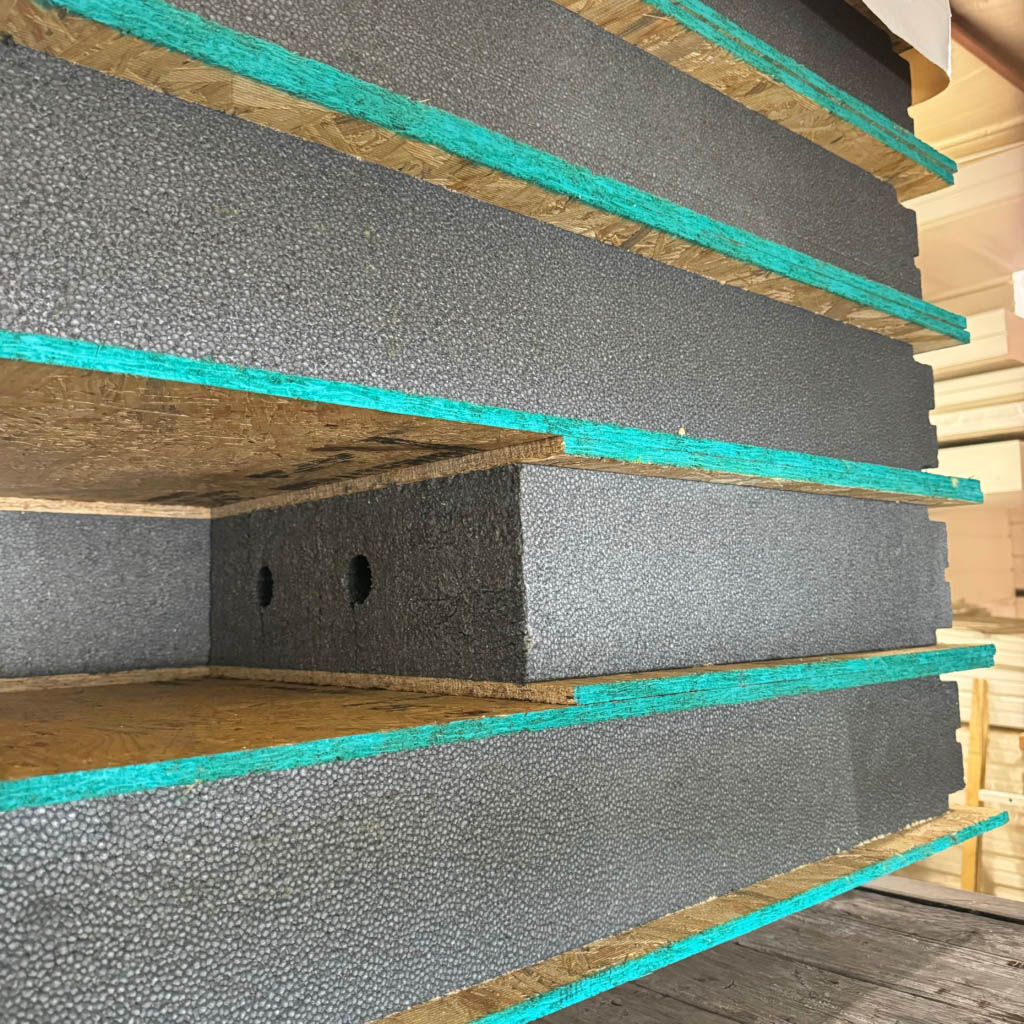

We provide the timber frame and structural insulated panels (SIPs) for this design.

- The Timber Frame:

Your choice of Eastern White Pine or Douglas Fir - The Structural Insulated Panels:

Your choice of EPS or GPS foam

To get a full plan set or to customize this design, please complete our Request an Estimate form to get started or call us at 802-453-3727 to ask questions.

Start Early:

Timber Frames and SIPs can accommodate almost any design vision you have, but it really helps to get us involved early, before the floor plan is finalized. This allows us time to provide input on things like placement of the timber posts, window locations that will work with the timber frame layout, and other structural and aesthetic considerations.

Please complete our Request an Estimate form to get started or call us at 802-453-3727 to ask questions.

Notes (click to open and close)