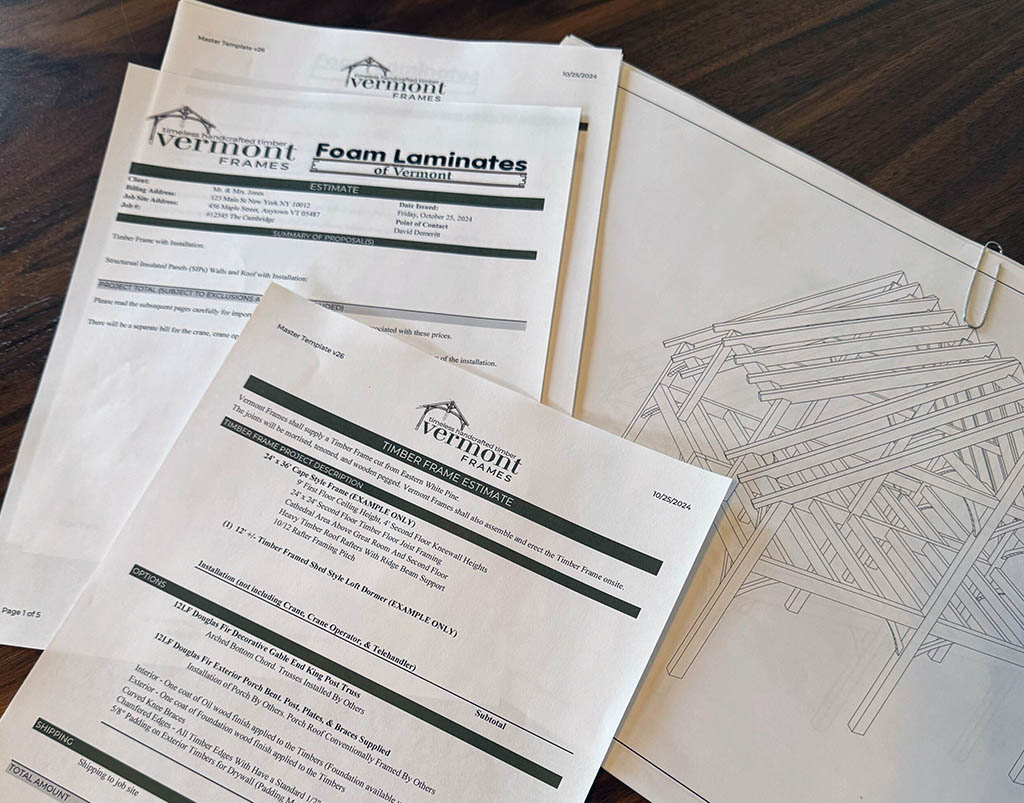

The estimate process begins with a review of a set of architectural plans. Ideally, those architectural plans will have been drawn with a timber frame and post locations in mind. If you don’t have plans yet, we will work to connect you with an architect who can develop them with you.

If you already have a set of plans meant for a conventionally framed home, we can work with your Architect to adjust them to effectively integrate our Timber Frame Design.

Very often, our clients are working with an Architect to develop a plan in parallel, as they seek our quote. This is ideal, as it gives us an opportunity to work with the architect before the plan is finalized, to take maximal advantage of the strengths of timber framing such as large, open-concept floor plans, cathedral ceilings, and exposed trusses – all in pursuit of your vision for your project. Once the estimate is agreed upon, we formalize the engagement with a contract that outlines the specific scope of the project and request a design fee to move forward into the Design Phase.

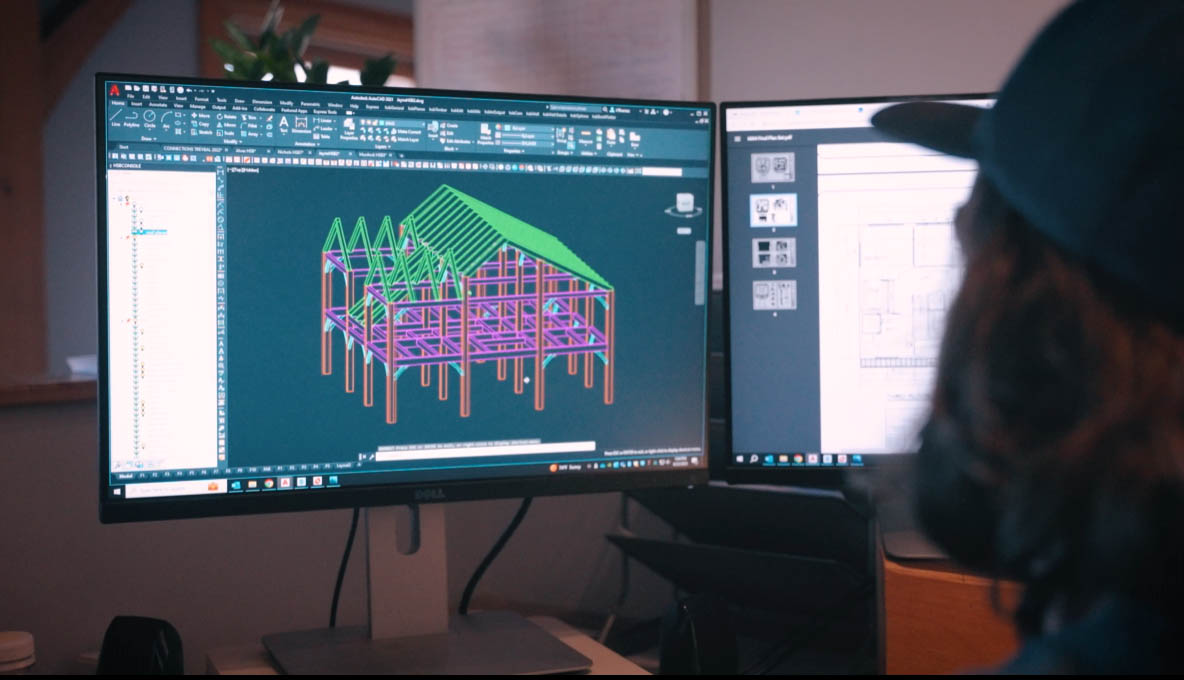

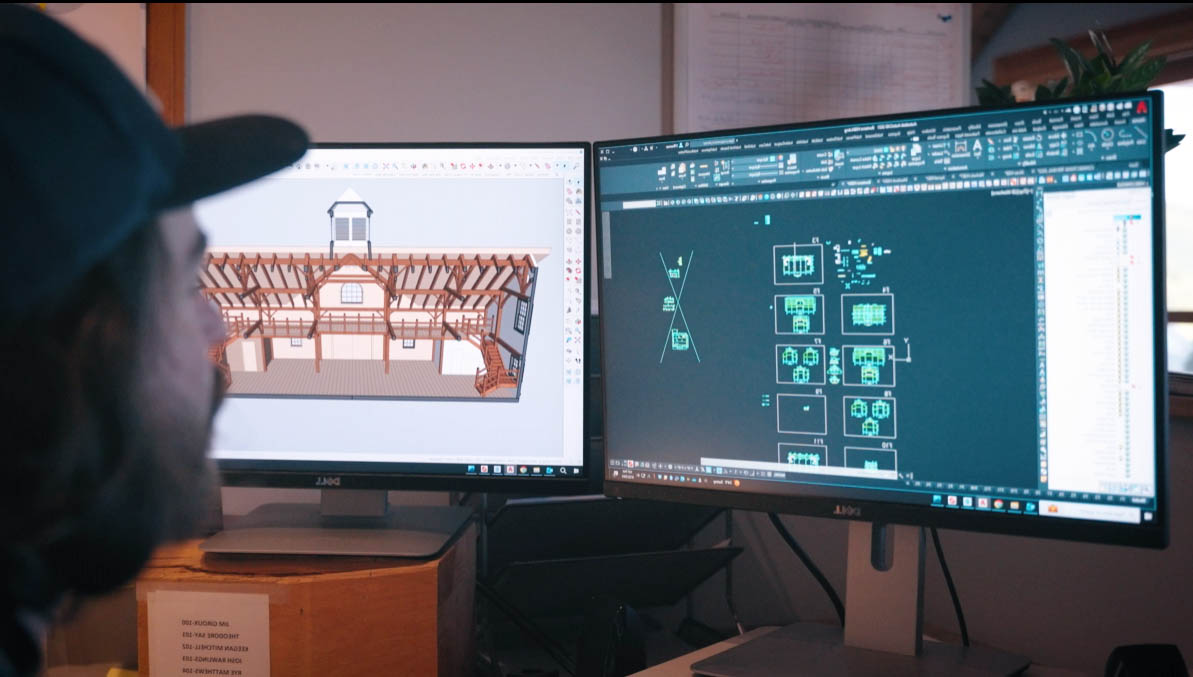

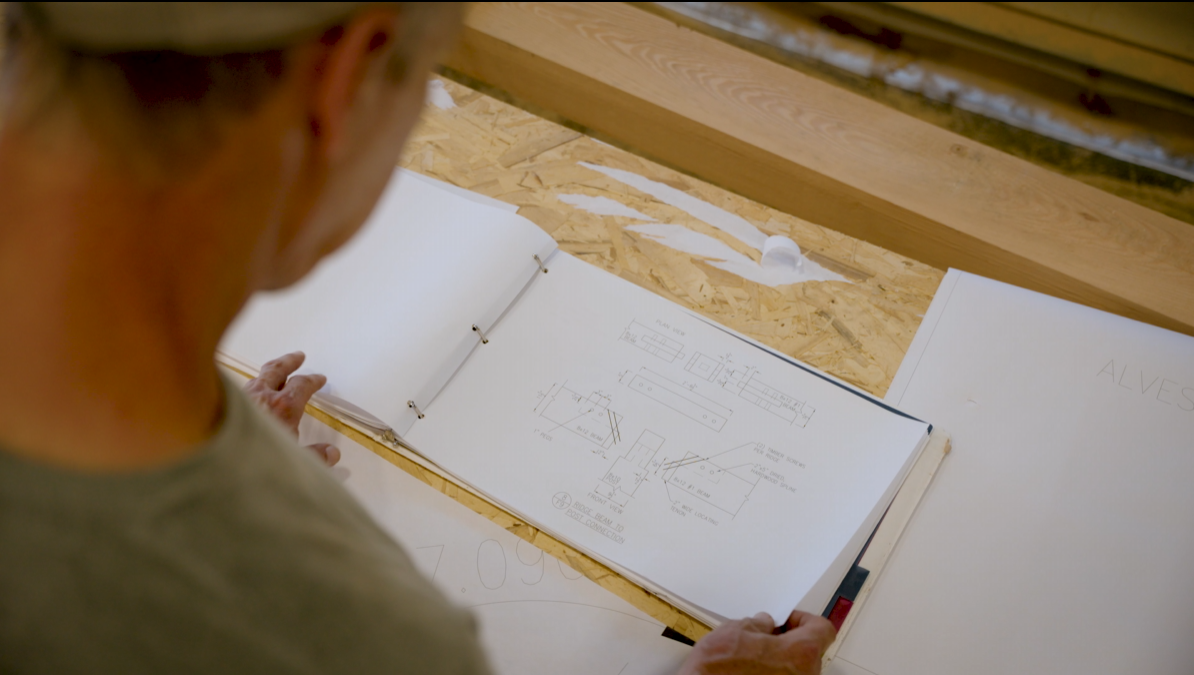

In the timber frame design phase, we draft our structural timber frame drawings to complement your architectural drawings. These timber frame drawings are used by our team to fabricate and install the timber frame. They show the location and size of all the timbers in the building and are critical to your architectural design team to help develop floor plans, window and door locations, foundation plans, etc. The builder, architectural designer, and client are all included in the process of developing the timber frame design.

Our Timber Frame Design Phase includes a first draft, second draft, and if necessary, a third draft, to make absolutely sure we get all the details of the frame design correct. Depending on the complexity of the project, the design may be sent to a structural engineer for review.

Once the architect, builder, and most importantly the client, are happy with the design, we ask the client to sign the drawings, signifying their acceptance of the design and formally ‘locking’ it. After the design is finalized and agreed upon, the project moves to the fabrication stage. This structured approach ensures that all elements are well-coordinated and that the final build meets both structural and aesthetic expectations. This authorizes us to move forward to the fabrication stage by requesting the Cutting Fee and ordering timbers.

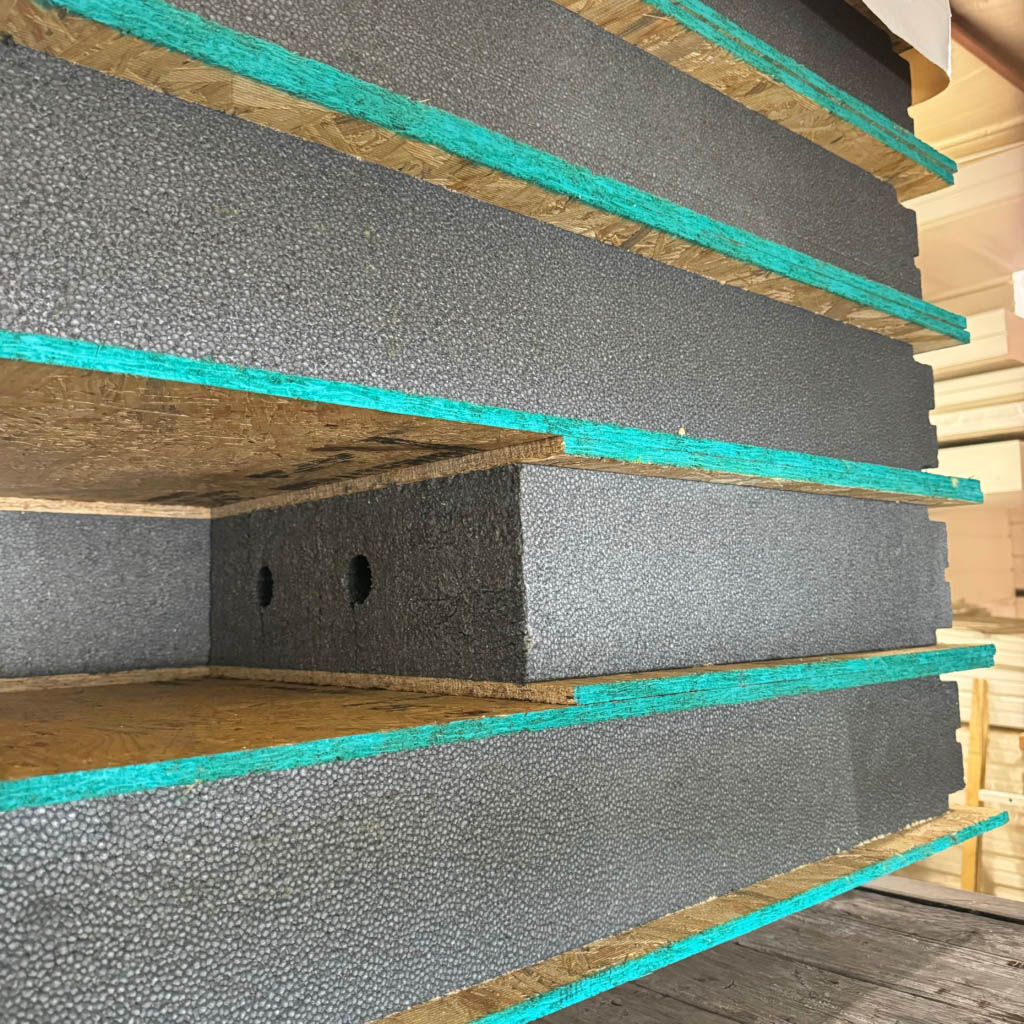

The delivery process is meticulously planned to ensure efficiency on site. Timbers and SIPs are bundled, stacked, and labeled in the order they will be assembled. This organization allows for a smooth assembly process once the timbers arrive at the site.

We depend on our clients for one of the most important steps of the delivery process: getting the site prepared and ready for our arrival. This includes ensuring we have access to the site and enough space on the site for our trucks loaded with full-length packages of timbers and panels to drive in and maneuver into the position. A well prepared site will be leveled, graded and graveled to facilitate the offloading of materials and movement of heavy equipment.

Timber frame packaged for delivery.

Example of well prepared job site.

This is where it gets real, really fast. Once our Foreman confirms with your builder that the foundation and deck are laid out according to plan, our dedicated installation crew and your timber frame/ structural insulated panels package show up – then the magic begins!

In one to two weeks, we’ll erect the timber frame using our own crane and then enclose it with our structural insulated panels. Bring your lawn chairs and enjoy the show—no kidding, people often show up with their friends to watch us work. Because everything was fabricated in our facility, it goes together precisely and cleanly, with almost no waste or mess on site. By the time we pull off your job site, you’ll have a fully enclosed structure, ready for your builder to install windows, doors, and take your new home across the finish line.

PLEASE NOTE: It’s important that job site preparedness is critical, as a messy or hard-to-access job site can dramatically slow down an installation and lead to costly delays.

Standard installations involve the full scope of designing, fabricating, and installing the timber frame and SIPs. In contrast, kit installations include all these steps but with a supervisor sent to oversee an installation performed by a third-party contractor.

The choice between standard and kit installations depends on logistics and cost considerations. Having a supervisor for kit installations is highly recommended as they bring specific tools and expertise necessary for proper assembly and greatly speed up the process. It is essential for clients to understand what is included and excluded in these installations to avoid any confusion.

The seamless coordination between our design, fabrication, and installation teams guarantees a swift and efficient process. The ultimate satisfaction of our clients is our greatest reward, knowing our timber frames will stand as symbols of craftsmanship and quality for generations.

Sign up to receive a copy of The Timber Frame Kit Handbook!

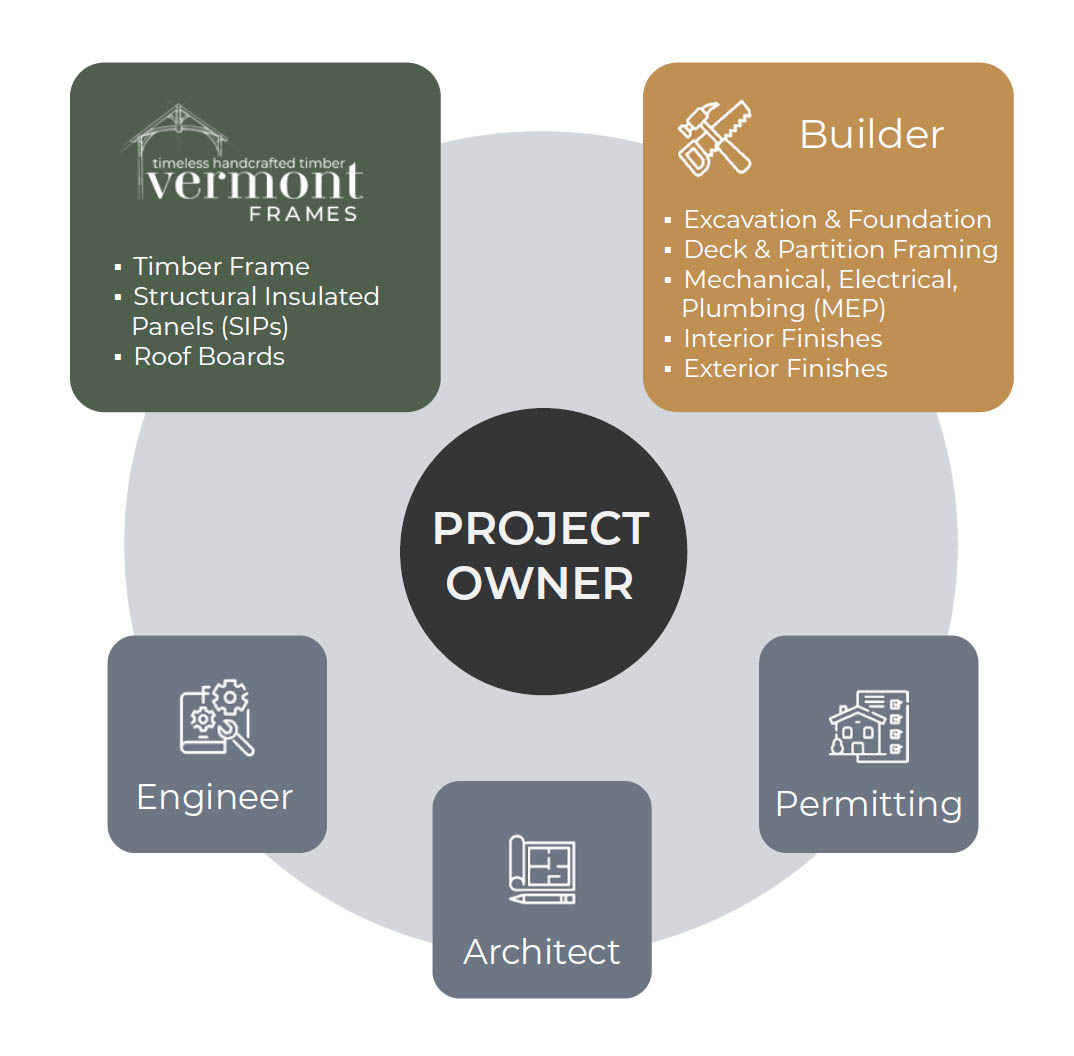

Build Team

The key ingredients to a successful project.

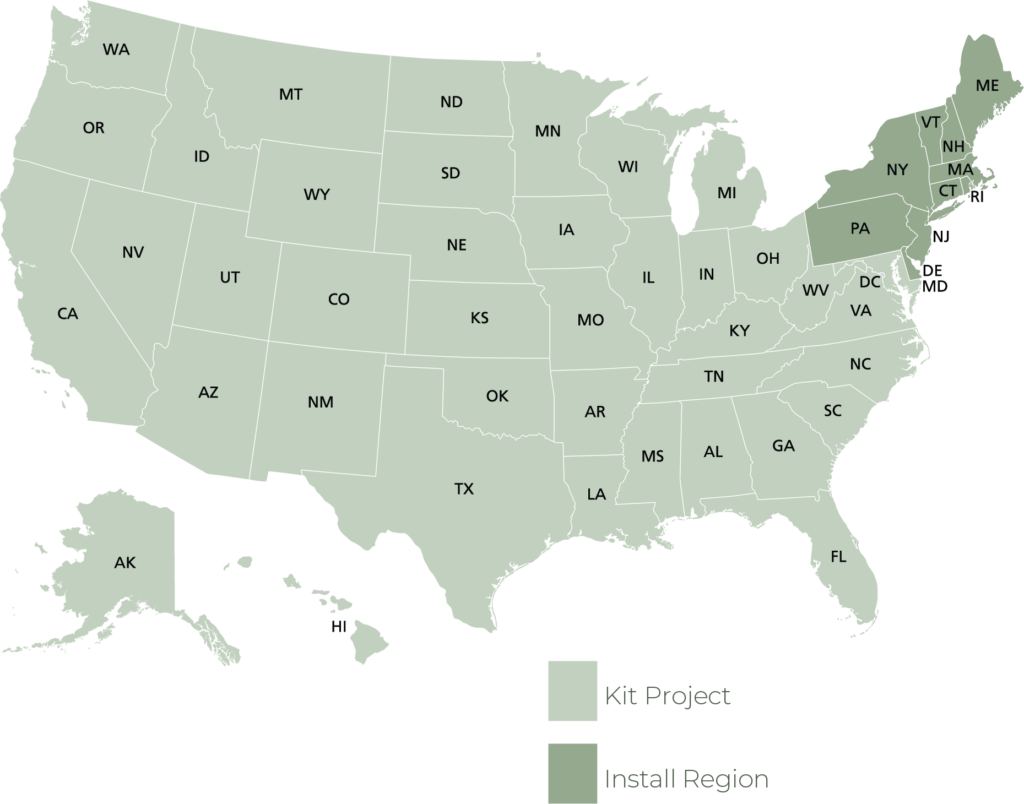

Service Area

Installs in the northeast. Kits everywhere else.